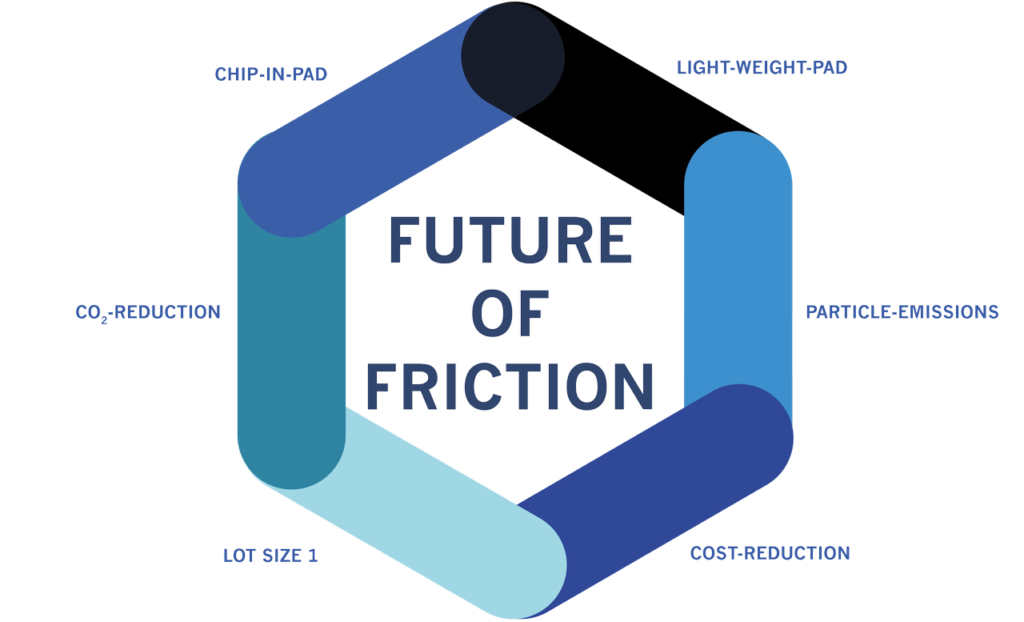

The great advantage of our material concept is the consistent use of a liquid material in comparison with the existing restrictions of a powder material approach in the manufacturing of friction linings. A number of application-related advantages can be derived from this. The high temperature stability obtained by the binder supports the required high temperature stability of friction linings in the future.

We would be happy to show you which savings potential can be achieved with our LIQFRIC® process.

The mean density of the LIQFRIC® friction material lies between 1,7 -1,9 g/cm³. This results in a geometry-dependent average weight saving of approx. 15% for the classic brake pad and backing plate combination.

We are trying to further optimize this weight saving

As we were able to demonstrate with one of our project partners, the emission of ultra-fine particles with inorganic friction lining materials escalates at significantly higher temperatures than with phenolic resin-bound materials. We want to investigate this phenomenon further in the future in order to be able to draw further benefits on this basis.

There are several points to consider here:

On the one hand, the use of energy for the manufacturing of the brake pad in large-scale production is significantly reduced through the savings in press hydraulics, the cross-linking temperatures and the process design.

On the other hand, the upstream mixing processes require less effort, so that overall lower production costs are incurred in the steady state.

.

Press tools for the production of friction lining materials and their rapid availability are another topic in which our LIQFRIC® technology can offer advantages. Thanks to the pressureless manufacturing process, for small series and prototypes we can dispense with the manufacturing of complex steel-based tools. The tools required can be manufactured using a 3D printing process or from corresponding polymer blocks. This means that prototypical friction linings and their geometric variations can be made available much quicker.

Going from your DXF- or CAD file to the finished tool is only one button press away.

Production-related process temperatures and their sequence in the production of the linings require a high level of thermal energy for the manufacturing of the brake linings. The multiple heating- and cooling cycles of the linings in production, and especially the steel backing plates, require a lot of energy.

Due to the low hardening and process temperatures, around 85% of the process energy currently required can be saved with phenolic bonded brake linings. In the case of sinter metallic linings, this value improves considerably, since the process temperatures are significantly higher.

Due to the systemically high pressures that occur in the production of brake linings, it has never been possible to integrate sensors into the friction lining matrix. However, the LIQFRIC® casting process allows sensors to be integrated and encased in the friction lining matrix. This makes it possible to analyze the condition control and the static and dynamic behavior of brake linings. For the first time, it is also possible to monitor lining wear in the sense of preventive maintenance. A large number of sensors can be integrated. Wireless communication between these sensors and the outside world is the next plausible development step in our strategy enabling internet of things (IoT) or internet of cars (IoC).