08-27-2020: Presentation of the LIQFRIC® CHIP-IN-PAD project with test drives at Griesheim Airport

10-05-2020: Article in "Atmosphere". Reduction of PM10 emissions through inorganic brake pads during the city traffic test cycle (WLTP). A joint study by FZD, IUTA, Daimler AG and LIQFRIC.

Please contact our advisory service for samples or existing results.

Contact us, we will process your request as soon as possible!

August 27th, 2020: A LIQFRIC® chip-in-pad friction material conducting tests at the airport of Griesheim on a premium vehicle platform.

LF GmbH & Co. KG with its brand LIQFRIC® has invited guests to a first meeting at the airport of Griesheim to present the results of their joint research work with Fraunhofer LBF on August 27th, 2020.

“We are proud to announce that we were able to invite a very limited number of guests to present the results of our piezo-sensor integration into our liquid friction materials during the molding process. We were able to test the cured and sensorized pads on a test dyno which was provided by Tribotecc GmbH. The data collected during a typical sequence of the AK-Master test series allowed our partner Fraunhofer LBF to analyze the performance of the sensors during brake actuation. These results and further details were presented to the audience during our meeting”, said Roman Milczarek, Director of R&D.

August 27th, 2020: Roman Milczarek during the company presentation

To complete the sensor experience, a vehicle provided by a well-known premium OEM was equipped with sensor pads on the front axle of the vehicle and hard wired into the back of the car to a multichannel reader/display system. Via this set-up, the participants of the presentation were allowed to see, probably for the first time, the real pressure conditions applied to a friction material during braking on the air field’s landing strip.

As one visitor said, the content and the combination of the results presentation, followed by an open discussion on the future potentials of this technology and the final real performance on a serial vehicle made the difference to most of the technical discussions he was part of before.

The ultimate goal of the company is to prepare the friction pad to become a player in the IoT in the future. The initial task may be to provide insights into the current operational work of friction brakes via calibrated measuring friction pads and allow for better understanding of braking activities while ultimately providing piezo-sensor pads for serial automotive applications.

“All of the above would not have been possible without the generous support and involvement we received. Therefore, I would like to thank:

added Roman Milczarek proudly.

LF GmbH & Co. KG was founded in Leverkusen in March 2016 and follows the strategic idea of producing friction materials based on a liquid friction compound that can be hardened at room temperature to make high-temperature stable friction lining materials for automotive, rail, and clutch- as well as industrial applications.

The company has entered development projects and collaborations with some key players in the brake- and clutch industry in Europe and especially in Germany.

LIQFRIC® is a registered trademark of LF GmbH & Co. KG.

Leverkusen, Germany

On July 27, 2020, the Smart Friction Factory went into operation with the first series-production machine for the

die-casting of friction linings at LIQFRIC®

LF GmbH & Co. KG with its brand LIQFRIC® has successfully completed the construction of a

first small-series production plant. Over the past two weeks, the system at the Leverkusen

site has been set up, programmed, and commenced production on July 27th.

"After about a year or approximately 1600 hours of engineering and mechatronic work, the

unit for our Smart Friction Factory is completed," explains Roman Milczarek, head of

development. "We are now implementing the first of several planned scaling steps to show

our project partners in the friction lining- and brake industry the potential of our LIQFRIC®

technology." Karsten D. and Ludwig W., responsible for the electronic control and the overall

project, explained that "this piece of equipment enables series manufacturing of friction

linings based on liquid LIQFRIC® compounds for the first time. The machine can adjust to the

various material properties in a time-adaptive manner, thus allowing flexible dosing of the

products into the dies and therefore creating a continuous manufacturing process. In

addition, the continuous capturing of operational data allows for optimization of the

products in terms of machine compatibility and development of the relevant parameters for

large-scale production in the next 2-3 years."

The unit can be operated by one person including all other downstream operations and is

able to produce up to 50,000 parts per year. The intention is to manufacture all future

prototypes and small-series parts on this machine. This includes manufacturing volumes

ranging from batch size 1 to larger test volumes, as well as series production.

"Based on the pressure-free production of brake pads, the possible small-series batch sizes

and further savings potential, in addition to the significant reduction of CO2 emissions in the

manufacturing process, we can ensure the monetization of efficiency gains," is Milczarek's

credo. “With our technological lead, we want to advance the production of high-tech brake

pads in Germany. If we combine our new production technology with the integration of

sensors in brake linings (e.g. NFC or others), we come close to the goal of innovative factory

systems and production controls in the theme of Industry 4.0.

Additionally, we focus on the use of our friction materials in electromobility, since our

friction materials bring about significant weight savings, while simultaneously providing

higher temperature stability compared to conventional friction linings.

LF GmbH & Co. KG was founded in Leverkusen in March 2016 and follows the strategic idea

of producing friction materials based on a liquid friction compound that can be hardened at

room temperature to make high-temperature stable friction lining materials for automotive,

rail, and clutch- as well as industrial applications.

The company has entered into development projects and collaborations with some key

players in the brake- and clutch industry in Europe and especially in Germany.

LIQFRIC® is a registered trademark of LF GmbH & Co. KG.

Leverkusen, Germany

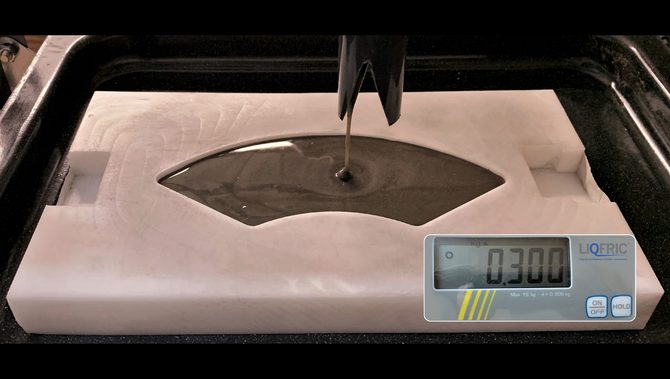

Semi-automatic filling of a mold with LIQFRIC® | © liqfric.com (Foto LF GmbH & Co. KG/ N. Wittig)

Small series production will start in July 2020.

LIQFRIC® is approaching serial use in the friction industry and the compounds are being extensively tested with potential customers. As announced in December 2019, LF GmbH & Co. KG is currently building a production line to lay the foundation for future business growth. This prototype line offers business partners and our internal material development team the basis for test options and the acquisition of unique experimental data based on series production. This production line, which cannot be bought ready, passed its first important step, a mechanical and operational fitness test, from March 11 to 13, 2020.

During the dry run, we were able to demonstrate for the first time that the design and the specially made equipment work mechanically according to our plan. In a second step, one of our LIQFRIC® compounds was filled into the machine and several molds could be filled with the compound within a reasonable process time.

The cooperation of the valves and the scale as well as all other support units have been coordinated. Although all steps were manually triggered and controlled to see that all critical elements of the process were working, a smooth operating process was achieved in the end. The next step will be to connect the components controlled by the microcontroller and the hardware. The integration will begin in the next six weeks to complete the operational setup of the manufacturing facilities.

Roman Milczarek, Head of Research and Development, commented: "We are certain that, based on these results, we will be able to combine our new LIQFRIC technology with an automatic feed and molding system from July 2020 to produce series parts ranging in size from 5,000 to 50,000 each Year can begin. This offers a unique opportunity for us and our prospect customers. You know it is fantastic to see your material work in this new dimension in mass production. "

Based on the initial learning curve from this operating experience, larger manufacturing units can be planned and parts falling in series can be made available to our business partners, and any scaling can soon start from here. The scale-up can be implemented via additional systems (multiplication) or by enlarging the system.

"LF GmbH & Co. KG has selected a number of strategic partners to develop their unique LIQFRIC material concept based on current and future strategic requirements, including aspects of electromobility," said Roman Milczarek. “We look forward to launching the first parts of our unique technology. We are very grateful that several business partners support our concept of alternative friction materials. "

“We are aware of the Covid 19 crisis and regret the impact it has on everyone around us and around the world, but we cannot allow this virus to hinder the advancement of technology. While protecting our employees and business partners from the spread of Covid-19, we will provide everything necessary to make progress on LIQFRIC®, ”said Roman Milczarek at the end.

LF GmbH & Co. KG was founded in Leverkusen in March 2016 and follows the strategic idea of producing friction material based on a liquid water-based compound that can be hardened at room temperature or faster at elevated temperature and supplies high-temperature stable friction lining materials for automotive , Rail, coupling and industrial applications.

The company has entered into development projects and collaborations with some key players in the brake and clutch industry in Europe and especially in Germany.

Leverkusen, Germany

During the most recent advisory board meeting the company has decided, due to the ongoing positive results of the projects with its unique LIQFRIC® technology, that an investment into the manufacturing capability of prototypes and small series products is needed.

The foundress of LF GmbH & Co. KG, U. Wittig, quoted: “Due to the strong interest expressed by several of our project partners, we have learned about the significant and increasing demand for our liquid friction technology. We strive to live up to the future demand with this investment.”

A manufacturing concept including a floor plan and a machine layout plan has been created for a prototype – or small series manufacturing line with a size-dependent annual capacity between 5.000 – 50.000 pieces of friction goods. The semi-automatic line will provide a variable capacity for the fields of application sampled so far. The line is targeted to become operational within the next 6-12 months.

“With this prototype line we will be able to demonstrate the capability of our alternative friction material concept in a serial manufacturing environment and expand the width of application as more potential volume will find its way to the LIQFRIC® material concept“ stated Roman Milczarek, director of R&D.

LF GmbH & Co. KG has selected a number of strategic partners to develop their LIQFRIC®-material concept based on the current and future strategic requirements including electromobility aspects. We are looking forward to 2020 which will become a breakthrough year for our company and the steady development of our core technology. We are very grateful to have several business partners supporting our concept of alternative friction materials.

LF GmbH & Co. KG was founded in March 2016 in Leverkusen, Germany and follows the strategic thought of producing friction material based on a two-component water-based liquid friction compound, that can be cured at room temperature (faster at elevated temperatures), and provides high-temperature stable friction materials for automotive, rail, clutch and industrial applications. The company has established developmental projects and cooperations with some key players in the brake – and clutch producing industry in Europe and most prominently in Germany.

12/19/2019 - Leverkusen, Germany

RFID chip (radio-frequency identification) embedded in a typical brake pad with reader

(Photo LF GmbH & Co. KG/ N. Wittig) -> Download:

Since its launch 3 years ago, LF GmbH & Co. KG has striven to achieve efficient energy management during the manufacturing process of friction pads. The resulting, greatly reduced resource input is an important advantage of our patented LIQFRIC® products from liquid phase.

The company has successfully proven the efficacy and practicability of this new concept of manufacturing clutch- and friction pads during the past months in various projects with several renowned project partners.

To be able to integrate active and passive sensors into friction pads, the chips are embedded into the liquid compound directly during the die-casting process. This isn’t possible with today’s conventional friction pads because of high temperatures and extreme pressure conditions during their manufacturing process (e.g. Sinter- or NAO pads).

“We have met one of our most important development goals of 2019! We have embedded a RFID chip into a brake pad for the first time. Based on our LIQFRIC® technology for the manufacturing of friction materials from liquid phase, we have embedded a preprogrammed chip during the die-casting process into a friction pad and successfully read it out.”

(R.. Milczarek, head of R&D at LF GMBH & CO. KG)

LF GmbH & Co. KG has started a collaboration with a renowned German research association on a project on integrating sensors into friction pads. First test results are expected in spring 2020.

Further developing sensor technology in brake pads for the user’s benefit is part of the platform strategy of LIQFRIC® - the first innovative brake pad from liquid phase.Integrated sensors allow for various future possibilities, for example:

LF GmbH & Co. KG was founded in 2016 with the goal of manufacturing friction materials by using a liquid die-casting process. The company is located in Leverkusen, where it develops, produces and distributes 2-component liquid friction compounds for the manufacturing of brake- and clutch friction materials.

For more information about LF GmbH & Co. KG and the brand LIQFRIC®, please visit our homepage: www.liqfric.com.

2019 EN 002

Thermal energy consumption up to 85% reduced.

The first brake pad from liquid phase.

2019 DE 002

Thermischer Energieeintrag bis zu 85% gesenkt.

Der erste Bremsbelag aus flüssiger Phase.

EB2019-MFM-002

Additive Manufacturing –

3D Printing of Friction Materials (2)

Water-based Liquid Friction Compounds

EB2018-MDS-005

Additive Manufacturing –

3D-Printing of Friction Materials